IMPLEMENTING ADVANCED OPTICS + 3D SCANNING

I have been with US Metal Crafters for a little over a year now. During this time I have seen a number of new updates, new processes, new machinery, and renewed growth. In my opinion, some of the most exciting changes have taken part in our Quality Assurance department.

QA is an essential part of any manufacturing business, not only does QA increase customer confidence but it also improves internal process and efficiency. We are dedicated to not just meeting quality standards but exceeding them. Fintegro, has a great diagram to explain the role of QA in product development:“QA makes sure that the end result meets the business and user requirements. It ensures the reliability of the application and satisfaction of the user and is a secret key to draw development of the business.” – Arine Baghdasaryan, Research Specialist

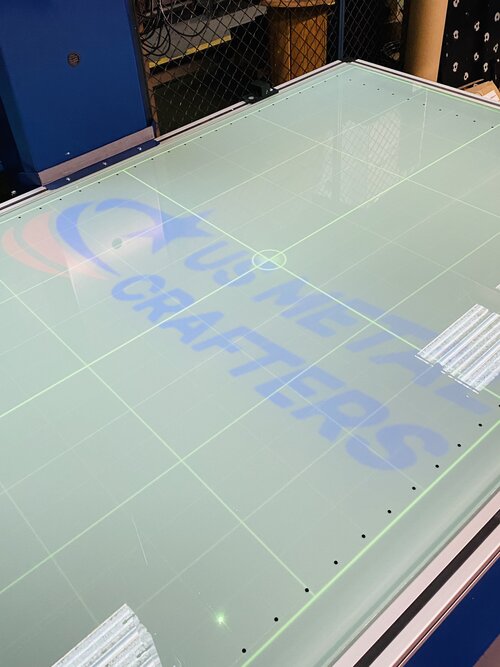

At US Metal Crafters, we are paving the way in what is the new standard quality assurance by implementing some of the most advanced technology 2020 has to offer. Our newest shop addition, the 3D Optic Planar Inspection System utilizes world-renowned QA technology providing uniform and actionable data. Not only can we ensure each first article meets specifications but we can ensure consistency across production runs and be alerted of any deviance with one click scanning ensuring we meet both customer demands and expectations.

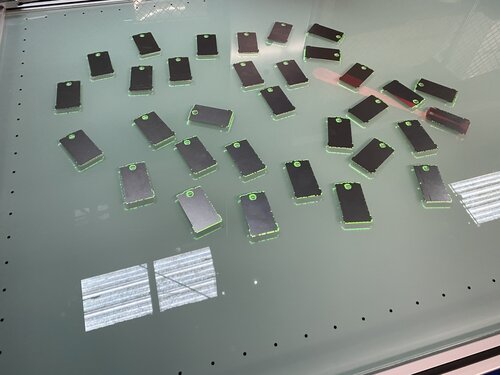

What makes the Opti-Scan Planar different is it is the world’s only system that can measure edges in 3D and read out accurate hole sizes and the true position of edges. Our Opti-Scan 3D measures edges in 3D with actual measurement data, not with the absence of data like other systems. Edge measurements are critical in measuring fold lengths and holes.

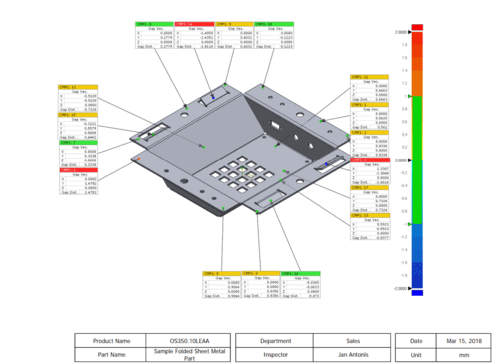

Opti-Scan 3D uses market leading white light scanning technology to scan formed parts. A White Light Scanner (WLS) is a device for measuring the physical geometrical characteristics of an object. It doesn’t stop there- the innovative Opti-Scan software then analyses the data to output a point cloud of the surfaces and edges of the object in a variety of report formats based on customer needs. Each scan can contain up to 40 million edge measurements and 20 million surface measurements.

For US Metal Crafters and our customers, this means we can accurately measure surfaces and edges in 3D, identify and resolve issues through single click inspection, complete instant product quality verification, reverse engineer from existing parts, & provide comprehensive report generation and CAD comparison.

Contact us to learn how our QA process can make a difference in your part development and production.

As the Marketing Manager at US Metal Crafters, Meredith Barnes is fully immersing herself in all things metal. Self-ascribed google search addict and chronic researcher; she’s discovering the world of metal crafting one Latte at a time. Follow along on her journey to metal here.