At US Metal Crafters, we provide a wide range of metal fabrication services to customers in the United States (we’re located in Archdale, NC) and beyond. In addition to our fabrication and assembly capabilities, we offer in-house powder coating services, ensuring the delivery of fully finished precision metal components and assemblies. Equipped with over 30 years of experience, a broad selection of standard and custom powder coating materials, and a powerful, highly accommodating powder coating oven, we are able to execute powder coated finishes for both simple and highly complex part requirements.

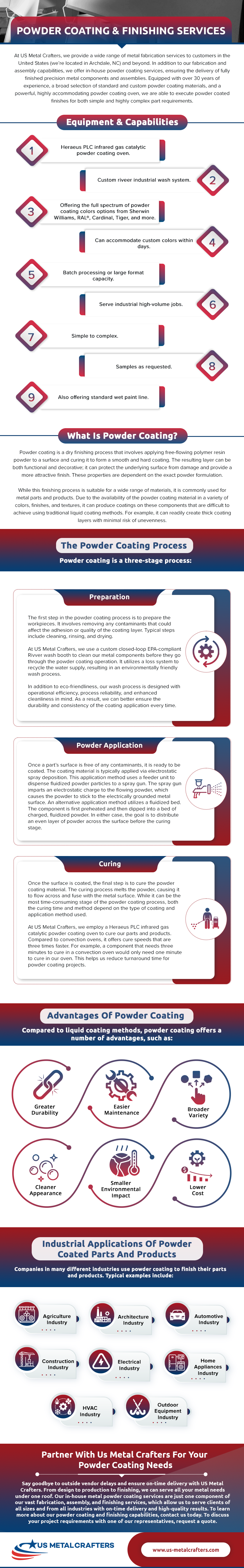

Equipment & Capabilities

- Heraeus PLC Infrared Gas Catalytic Powder Coating Oven

- Two spray booths to ensure full powder coverage

- Custom Riveer Industrial Wash System

- Automatic drying systems for improved quality and efficiency

- Offering the full spectrum of powder coating color options from Sherwin-Williams, RAL®, Cardinal, Tiger, and more

- Can accommodate custom colors within days

- Batch processing or large format capacity

- Serve industrial high-volume jobs

- Simple to complex

- Samples as requested

- Also offering standard wet paint line

Powder Coating Services

Our Powder Coating Oven

- 3:1 Rule For every 3 mins to cure a part in a convection oven, it only requires 1 min in a Gas Catalytic Infrared oven. Our powerful Heraeus PLC Infrared Gas Catalytic Powder Coating Oven is cost-effective and designed for industrial powder coating with a large drying capacity that is three times faster than traditional powder coating ovens.

Environmentally-Friendly Wash Process

- Is ensured through our custom closed-loop EPA Compliant Rivver Wash Booth. Our wash process provides operational efficiency, process reliability, and enhanced part cleanliness meaning your parts will have a durable and consistent coating application every time.

Full Spectrum of Standard & Custom Coatings

- We have a large variety of in-stock colors to select from brands such as Sherwin Wiliams, RAL, Cardinal, and Tiger and can have additional colors in stock within 24 hours. Custom colors sourced in days.

Looking to learn more about powder coating? Check out general information about the process below.

What Is Powder Coating?

Powder coating is a dry finishing process that involves applying free-flowing polymer resin powder to a surface and curing it to form a smooth and hard coating. The resulting layer can be both functional and decorative; it can protect the underlying surface from damage and provide a more attractive finish. These properties are dependent on the exact powder formulation.

While this finishing process is suitable for a wide range of materials, it is commonly used for metal parts and products. Due to the availability of the powder coating material in a variety of colors, finishes, and textures, it can produce coatings on these components that are difficult to achieve using traditional liquid coating methods. For example, it can readily create thick coating layers with minimal risk of unevenness.

The Powder Coating Process

Powder coating is a three-stage process:

Preparation

The first step in the powder coating process is to prepare the workpieces. It involves removing any contaminants that could affect the adhesion or quality of the coating layer. Typical steps include cleaning, rinsing, and drying.

At US Metal Crafters, we use a custom closed-loop EPA-compliant Rivver wash booth to clean our metal components before they go through the powder coating operation. It utilizes a loss system to recycle the water supply, resulting in an environmentally friendly wash process.

In addition to eco-friendliness, our wash process is designed with operational efficiency, process reliability, and enhanced cleanliness in mind. As a result, we can better ensure the durability and consistency of the coating application every time.

Powder Application

Once a part’s surface is free of any contaminants, it is ready to be coated. The coating material is typically applied via electrostatic spray deposition. This application method uses a feeder unit to dispense fluidized powder particles to a spray gun. The spray gun imparts an electrostatic charge to the flowing powder, which causes the powder to stick to the electrically grounded metal surface. An alternative application method utilizes a fluidized bed. The component is first preheated and then dipped into a bed of charged, fluidized powder. In either case, the goal is to distribute an even layer of powder across the surface before the curing stage.

Curing

Once the surface is coated, the final step is to cure the powder-coating material. The curing process melts the powder, causing it to flow across and fuse with the metal surface. While it can be the most time-consuming stage of the powder coating process, both the curing time and method depend on the type of coating and application method used.

At US Metal Crafters, we employ a Heraeus PLC infrared gas catalytic powder coating oven to cure our parts and products. Compared to convection ovens, it offers cure speeds that are three times faster. For example, a component that needs three minutes to cure in a convection oven would only need one minute to cure in our oven. This helps us reduce turnaround time for powder coating projects.

Quality Checks

To ensure our work is the best out there, all products go through three rigorous checks

- MEK rub test

- Mil thickness test

- Cross hatch adhesion test

Advantages of Powder Coating

Compared to liquid coating methods, powder coating offers a number of advantages, such as:

- Greater durability: Powder coatings protect components against moisture, chemical, and weather. Additionally, they resist damage from impact and abrasion better than their liquid coating counterparts.

- Easier maintenance: Since powder coatings are highly durable, they generally require less touch-up work than liquid coatings, even when used in demanding or outdoor environments.

- Broader variety: Powder coating materials are available in a wide range of colors and finishes to suit different aesthetic needs. Options available include flat and satin to textured and glittery. Similarly, the powders can be formulated to demonstrate specific functional properties (e.g., moisture resistance, UV resistance, etc.)

- Cleaner appearance: Powder coatings look clean and professional. Additionally, since they are highly customizable, they can be tailored for different decorative requirements and, since they are highly durable, they remain attractive for extended periods.

- Smaller environmental impact: Unlike liquid coating processes, the powder coating process does not use solvents or produce hazardous waste, both of which can be harmful to people and the environment. Additionally, it allows excess coating materials to be recaptured and reused, resulting in less material waste.

- Lower cost: The same characteristics that make powder coating environmentally friendly also make it cost-effective. As the process eliminates the emission of VOCs, facilities can cut down on pollution-control measures and equipment. Additional savings come from reclaiming excess powder after spraying, which helps manufacturers cut down on material costs.

Industrial Applications of Powder Coated Parts and Products

Companies in many different industries use powder coating to finish their parts and products. Typical examples include:

- Agriculture industry: plows, tractors, trailers, storage units, and other farming equipment and vehicles

- Architecture industry: benches, doors, fences, gutters, railings, signs, and windows

- Automotive industry: bumpers, car frames, door and window handles, shock absorbers, wheels, and other high-use or high-stress components

- Construction industry: structural elements (e.g., metal curtain walls and roofs) and heavy equipment (e.g., cranes and forklifts)

- Electrical industry: cabinets, connectors, fixtures, motor housings and windings, switch gears, and transformers

- Home appliances industry: dishwashers, freezers, ranges, refrigerator doors and shelves, vacuum cleaners, and washing machines and dryers

- HVAC industry: boilers, furnaces, heaters, radiators, and ventilation ducts

- Outdoor equipment industry: bicycle shelters, golf carts, lawn chairs, playgrounds, ski poles, and other recreational structures and equipment

Partner With US Metal Crafters for Your Powder Coating Needs

The metal fabrication team at US Metal Crafters provides powder coating services for components simple and complex, and for larger-scale production volumes. We offer a full spectrum of powder coating color options from reputable brands, including Sherman Williams, RAL®, Cardinal, Tiger, and more. Additionally, we can accommodate custom color orders within days. Samples are available upon request for color, finish, and texture verification.

Say goodbye to outside vendor delays and ensure on-time delivery with US Metal Crafters. From design to production to finishing, we can serve all your metal needs under one roof. Our in-house metal powder coating services are just one component of our vast fabrication, assembly, and finishing services, which allow us to serve clients of all sizes and from all industries with on-time delivery and high-quality results. To learn more about our powder coating and finishing capabilities, contact us today. To discuss your project requirements with one of our representatives, request a quote.

Download Our Free Guide

In “The Ultimate Guide to Powder Coating”, you’ll discover how powder coating works, types of powder coating material, advantages of powder coating, how to select the right powder coating service provider, and more! Fill out the form below to download your copy.