Precision Laser Cutting Services

Nationwide Solutions from US Metal Crafters

US Metal Crafters provides high-precision laser cutting services as part of our full-service metal fabrication solutions, serving industrial and commercial clients across the United States.

Why Choose US Metal Crafters for Laser Cutting?

- High-Precision Tolerances: Laser cutting to ±0.003–0.006mm for exceptional accuracy and repeatability.

- Versatile Material Capability: Cuts steel, stainless, aluminum, and more – up to 1.5″ thick!

- Full-Service Fabrication: 3K-15K lasers integrated with forming, welding, powder coating, and assembly under one roof.

- Fast Turnarounds: Streamlined production eliminates delays from outsourcing.

- Quality Assurance You Can Trust:

- 3D scanning inspection

- Real-time KPI tracking

- Multi-tier quality checks

Industries We Serve:

- OEMs and contract manufacturers

- Automotive and transportation

- Agricultural and heavy equipment

- Industrial and commercial product manufacturers

Service Highlights:

- Based in North Carolina, serving customers nationwide

- Scalable for medium to large production runs

- Expert team with advanced laser cutting technology

Contact us today to learn how our laser cutting capabilities can enhance your production quality and efficiency.

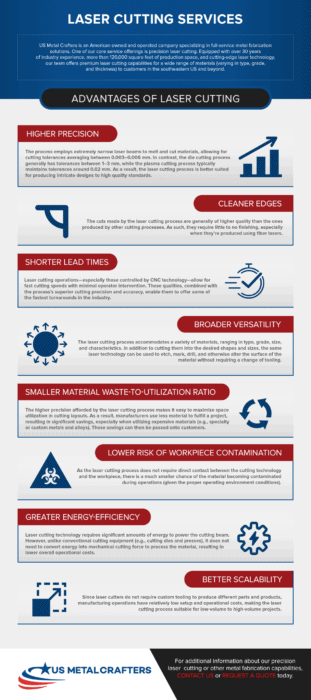

Advantages of Laser Cutting

Some of the advantages to laser cutting services can be seen in our below infographic. These include:

- Higher precision

- Cleaner edges

- Shorter lead times

- Broader versatility

- Smaller material waste-to-utilization ratio

- A lower risk of workplace contamination

- Greater energy efficiency

- And better scalability

You can also learn more about Laser Cutting by downloading our free e-book, The Ultimate Guide to Laser Cutting,

here.

Common Materials Used in Laser Cutting Operations

One of the key advantages of the laser cutting process is its versatility—i.e., its ability to handle a variety of materials. In industrial manufacturing operations, laser cutters are generally used to process metals. While the term “metals” encompasses a wide range of materials, some of the ones most commonly used in laser cutting are:

- Aluminum. Aluminum is a popular construction material for a variety of industrial components. However, its reflective surface can make processing it with standard laser technology challenging since there is a risk of the laser beam bouncing back. For this reason, manufacturers employ high-powered CO2 or fiber lasers (at least 250 watts) when processing aluminum, as they have the power necessary to pierce through the workpiece and produce a quality cut.

- Brass. Laser cut brass components are used for both functional and decorative applications. The conductivity of the materials make them well-suited for use in electrical and electronic assemblies.

- Stainless steel. Stainless steel is available in several grades—e.g., austenitic stainless steel, duplex stainless steel, ferritic stainless steel, and martensitic stainless steel—each of which offers unique characteristics that make it suitable for different applications. Two of the most common grades are austenitic and ferritic stainless steel, both of which readily accommodate the laser cutting process.

- Mild steel. Mild steel—also referred to as low-carbon steel—is a steel alloy that contains between 0.05–0.25% carbon by weight. Compared to other steel alloys, it is more ductile, machinable, and weldable and less expensive. It is used in the laser cutting operations for both 2D and 3D components.

Types of Laser Cutting Equipment at US Metal Crafters

Laser cutting units can be categorized into one of three classifications based on the state of the active laser medium: gas, liquid, or solid-state. The type employed in a laser cutting operation—and its configuration—varies depending on the part and production specifications.

At US Metal Crafters, we employ two fiber lasers for our laser cutting operations: a Mazak 3000-watt Optiplex Champion 3015 and a Mazak 8000-watt Optiplex Champion 3015. Fiber lasers fall under the solid-state laser category, relying on optical fibers to transmit, amplify, and focus the laser beam during cutting operations. Compared to CO2 lasers (lasers with a gaseous active laser medium), they offer higher precision, better edge finishes, greater energy-efficiency, and faster cutting speeds. Equipped with these two laser cutting units, we can accommodate laser cutting projects involving aluminum, brass, copper, stainless steel, mild steel, and exotic alloys in thickness ranging from 0.01–0.5 in.

In addition to our laser cutting equipment, we maintain a full range of other manufacturing units to support our laser cutting operations. For example, our facility is equipped with a Safan Darley Brake 100-ton premium automatic press brake, which allows us to offer bending services. Other service offerings include grinding, assembly, painting, anodizing, and powder coating.

Applications of Laser Cutting

Some examples of typical laser cut parts and products include brackets (structural or decorative elements used to support other components) and chassis/enclosures (partially or fully enclosed structures used to house electrical and electronic components).

Contact the Laser Cutting Experts at US Metal Crafters Today

Laser cutting offers many manufacturing advantages, including with regard to cutting precision, accuracy, and speed. At US Metal Crafters, we are fully aware of these qualities and how they benefit industrial companies. As such, we offer precision laser cutting services to customers from a wide range of industries—including aerospace, agriculture, furniture, hardware, solar, and more—in the southeastern and other areas of the United States. By partnering with us for their laser cutting needs, they benefit from our:

-

- Extensive industry experience (over 32 years of combined experience)

- Expansive production space (over 120,000 square feet)

- Broad manufacturing capabilities (accommodates simple/complex designs, various metals, and short/long run production volumes)

- Competitive pricing

- Fast lead and delivery times (typical lead times of two to four weeks)

For additional information about our precision laser cutting or other metal fabrication capabilities, CONTACT US or REQUEST A QUOTE today.

Laser Cutting Capabilities

- Mazak 3000 W Fiber Laser

- Mazak 8000 W Fiber Laser

- Programmable, Automatic Press Brake

LASER CUTTING SPECIFICATIONS

| Cutting Axis | 3-Axis |

| Max. Power Output | 8000 W |

| Automation | Sheet Load/Unload |

| Materials | Mild Steel, Stainless Steel, Aluminum |

| Mild Steel Cutting Thickness | Up to 1” |

| Stainless Steel Cutting Thickness | Up to 1″ |

| Aluminum Cutting Thickness | Up to 5/8” |

| Cutting Length | Up to 10’ |

| Cutting Width | Up to 5’ |

| Accuracy | ± .002 |